How to Change Caterpillar Wheel loader 924 Engine Oil and Filter

Here is the English translation of the article, formatted and polished to be suitable as a professional blog post for your readers.

🛠️ A Step-by-Step Guide: How to Replace the Oil Filter on a Cat 924

Maintaining your heavy equipment is the key to maximizing uptime and extending the life of your investment. If you are the owner or operator of a Caterpillar 924 (such as a 924 wheel loader), performing routine maintenance like an oil and filter change is a fundamental task.

While specific schematics for the 924 model were not found in the provided search results, the following steps are based on standard heavy equipment maintenance practices and Caterpillar specifications. Always refer to your specific machine’s Operation and Maintenance Manual for the most accurate fluid capacities and torque specifications.

Here is a comprehensive guide to help you get the job done right.

🧰 Preparation and Safety

Before you begin, ensure you have the correct tools and parts on hand. Safety is paramount when working around heavy machinery.

- Cool Down: Ensure the engine is OFF and has had time to cool down to prevent burns from hot oil.

- Gather Supplies:

- A new Cat® oil filter (or an OEM-equivalent that meets Caterpillar specifications).

- A clean oil fill funnel.

- A drain pan or bucket (large enough to catch the oil).

- Wrenches or a filter wrench.

- Nitrile or work gloves.

Note: Using genuine Cat filters is recommended to ensure the correct micron rating (typically filtering particles >30μm) to protect your engine from wear.

📝 Step-by-Step Replacement Procedure

1. Drain the Old Oil

To ensure you get all the contaminants out, you must drain the old oil before removing the filter.

- Locate the drain plug on the bottom of the oil pan or transmission (depending on which filter you are changing).

- Position your drain pan underneath.

- Carefully loosen the drain plug. Oil will flow out quickly at first.

- Once the flow slows to a trickle, you may use a suction pump or vacuum to remove the last remnants of oil to ensure a thorough change.

- Reinstall and tighten the drain plug securely.

2. Remove the Old Filter

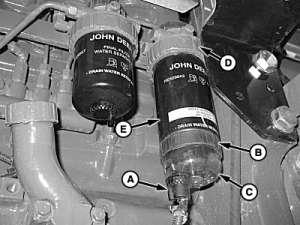

- Locate the oil filter housing. On many Cat machines, this is easily accessible on the side of the engine block.

- Place your drain pan underneath the filter to catch residual oil.

- Using a filter wrench, turn the old filter counterclockwise to loosen and remove it.

- Inspect the Mounting Surface: Before installing the new part, inspect the filter base and the mating surface on the engine. Look for any debris, old gasket material, or signs of damage. Clean the surface thoroughly if necessary.

3. Install the New Filter

This step is critical for preventing leaks.

- Lubricate the Seal: Apply a thin film of clean engine oil to the rubber gasket (seal) on the top of the new filter. This ensures a proper seal and prevents dry rubbing.

- Check the Direction: Ensure the filter is oriented correctly. If the filter has a directional arrow, it should point in the direction of oil flow. If there is no arrow, the writing on the filter should generally face outward/upward for visibility.

- Hand Tighten: Screw the new filter on by hand. Tighten it until the gasket makes contact with the engine base, then give it an extra 3/4 to 1 full turn (or as specified in your manual). Do not over-tighten with a wrench, as this can damage the seal and cause leaks.

4. Refill and Check

- Replace the oil fill cap and pour in the new oil, adhering to the capacity specified in your Cat 924 manual.

- Start the engine and let it run for a few minutes.

- Check for Leaks: Observe the new filter and the drain plug area for any signs of seepage.

- Finally, check the oil level on the dipstick and top off if necessary. Also, verify that the oil pressure gauge reads normally.

⏱️ Maintenance Tips

- Frequency: It is standard practice to change the oil filter every time you change the oil. For a Cat 924, based on operating hours.

- Environment: If your machine operates in dusty or high-risk environments (like oil & gas or mining), you may need to shorten this interval.

By following these steps, you can keep your Cat 924 running smoothly and efficiently for years to come.

*Disclaimer: The information provided is for general guidance based on standard practices. Always consult your specific machine’s service manual for safety protocols and exact specifications.